Description

- Built on the award winning HotSense™ ultrasonic platform powered by the proprietary Ionix HPZ piezo-ceramic, and offering increased heat resilience.

- -55 to +350 °C [-67 to +662 °F] continuous use temperature range.

- No cooling required. Increase your productivity by reducing duty cycling.

- High sensitivity with integrated wedges across the temperature range.

- Compatible with commercial scanners and crawlers.

- Stable signal for reliability and repeatability – no duty cycling means no drift from thermal gradients in the wedges.

- Short approach to beam exit to get closer to weld caps.

- Enhanced wear resistance for the most extreme environments and applications.

- Make weld inspections on hot assets, on-stream, without the need to shutdown or isolate.

- Make effective weld root corrosion assessments rapidly at high-temperature.

- Detect and size cracks or defects in welds or parent material on-stream.

- Screen for HTHA in-service.

- TOFD carries the highest POD for NDT methods

Be ready for any weld inspection with a complete set of HotSense™ Time-of-Flight Diffraction (TOFD) transducers for on-stream inspection of a wide range of welds, depths and vessel diameters.

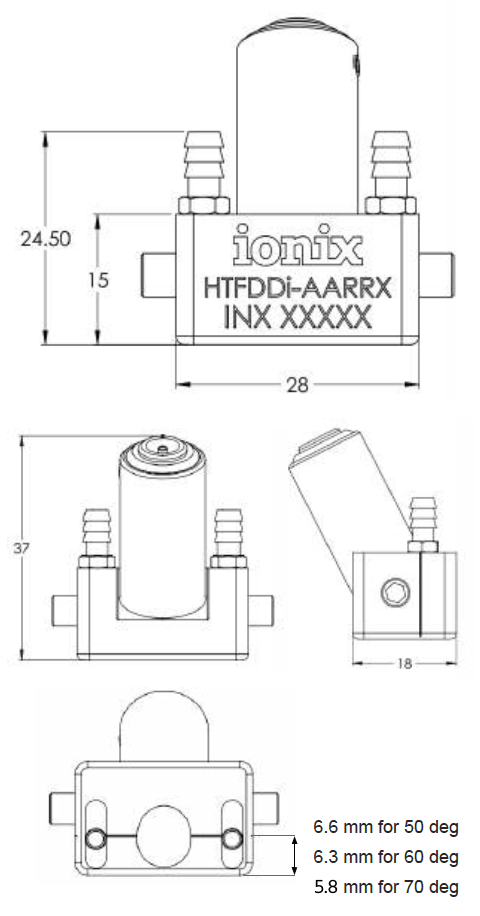

- Complete set of HotSense™ TOFD probes (24 probes) with integrated 50, 60 and 70˚wedges with flat, 8”, 12” and 16” profiles to cover pipe diameters from 6″ NPS to flat.

- Includes high-temperature couplant feed tubing, splitters and high-temperature cables.

- HotSense™ TOFD protective case with cut-outs for 24 HotSense™ TOFD Probes, cables and accessories.

Compatible with UT flaw detectors and scanners

*Refracted angle temperature dependence on steel

**Other variations available via special request

IONIX TOFD Brochure

IONIX TOFD Brochure